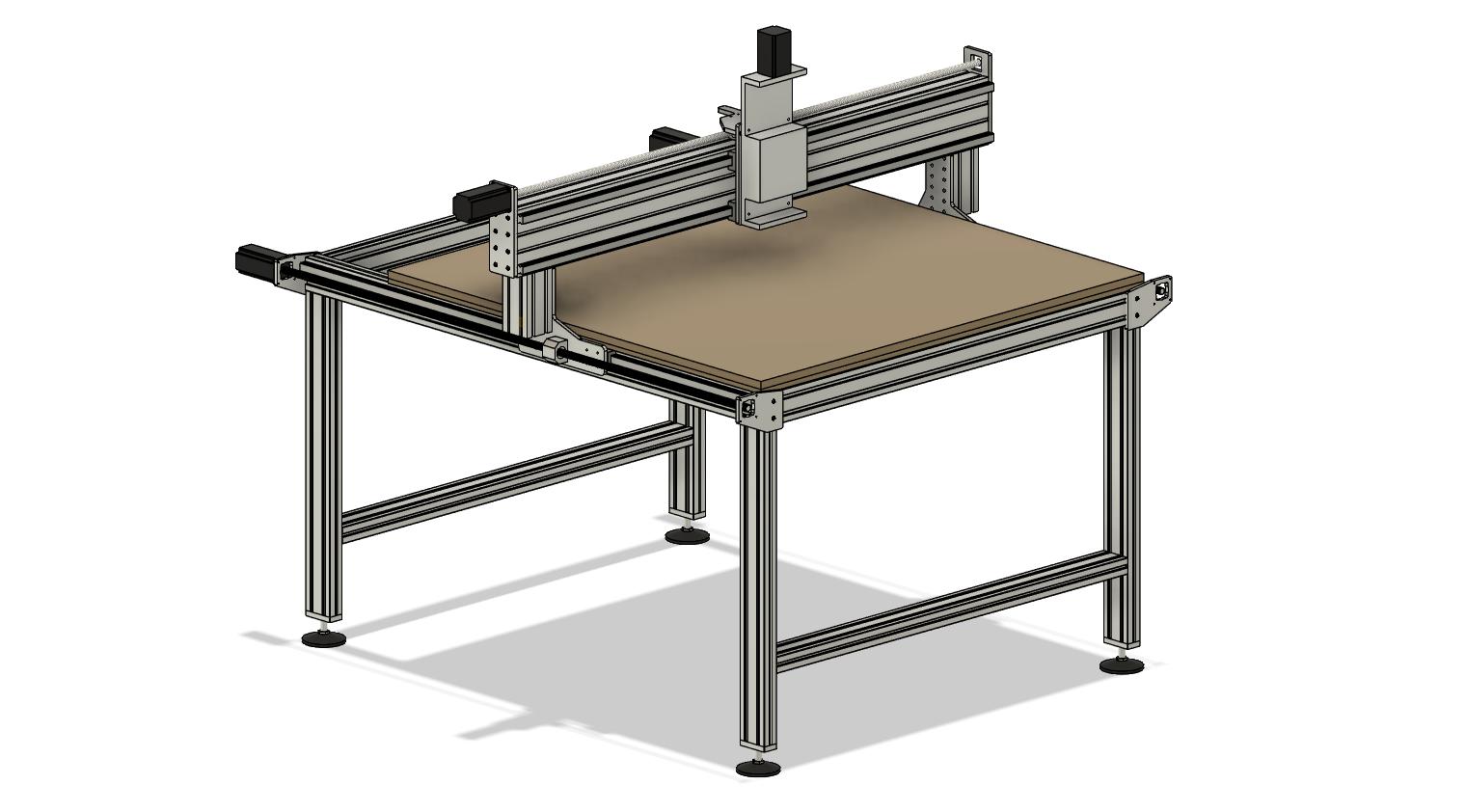

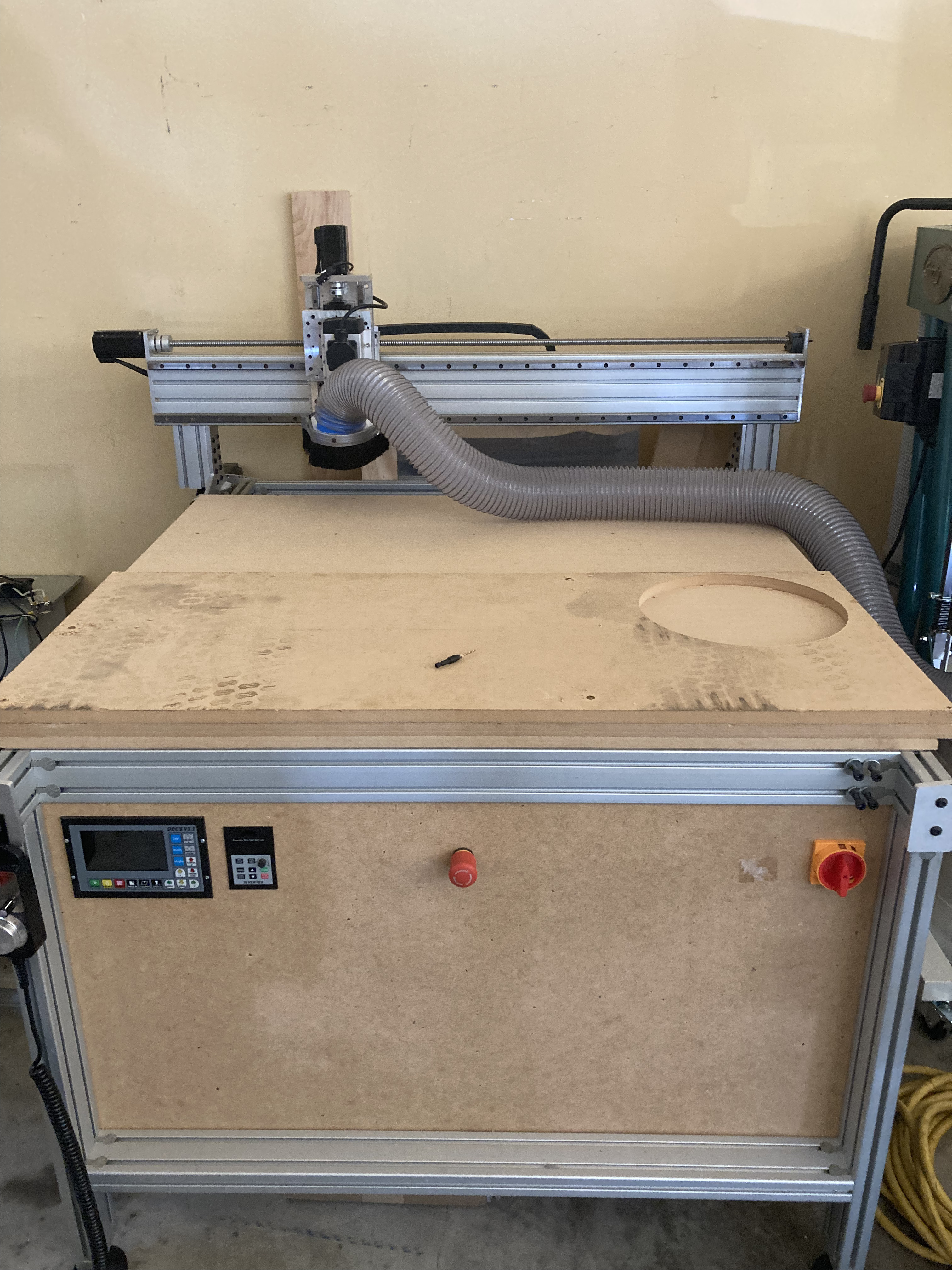

Custom Designed CNC Machine

From concept to a fully functional CNC machine: CAD design, fabrication, wiring, and G-code programming.

Overview

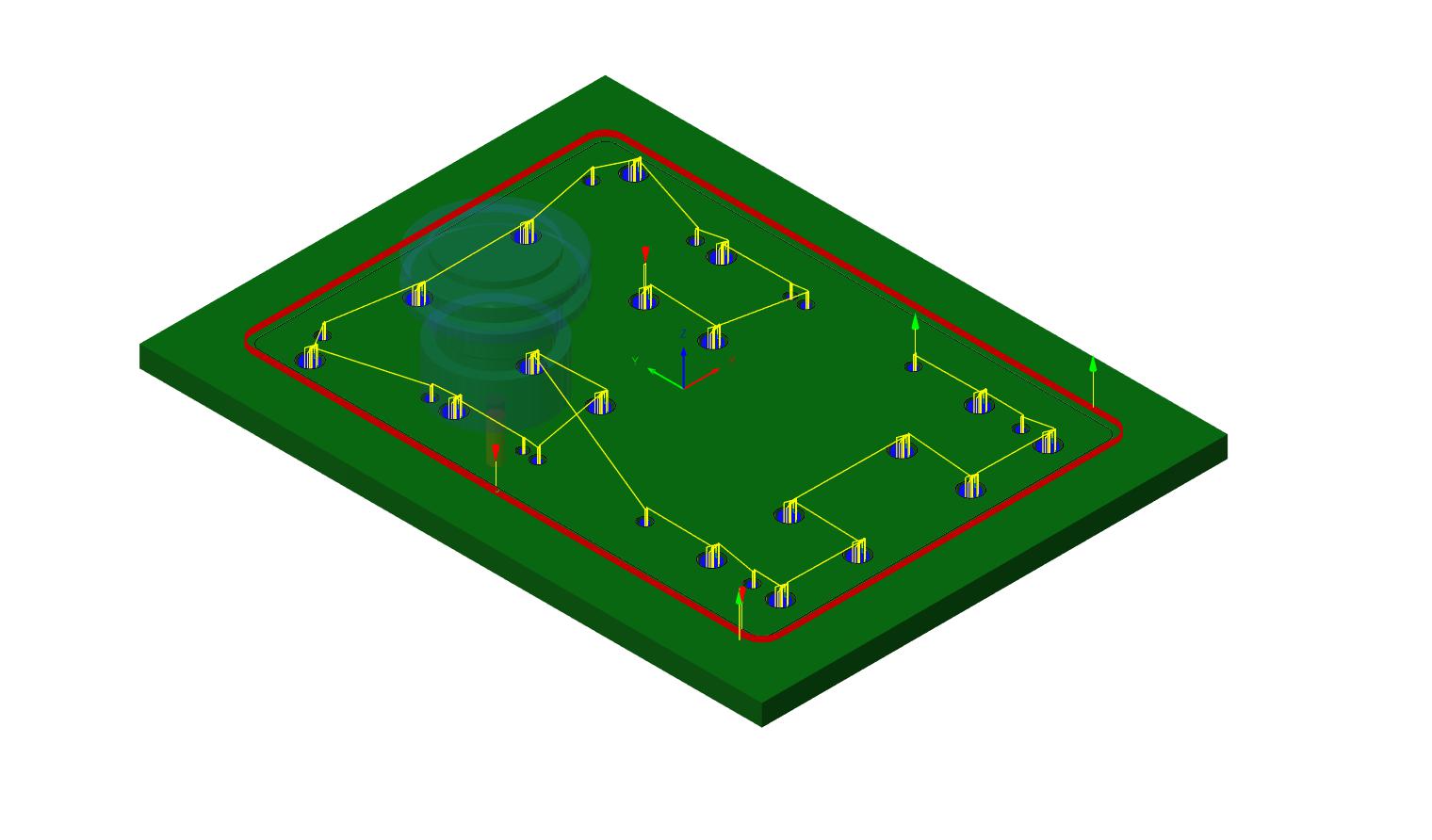

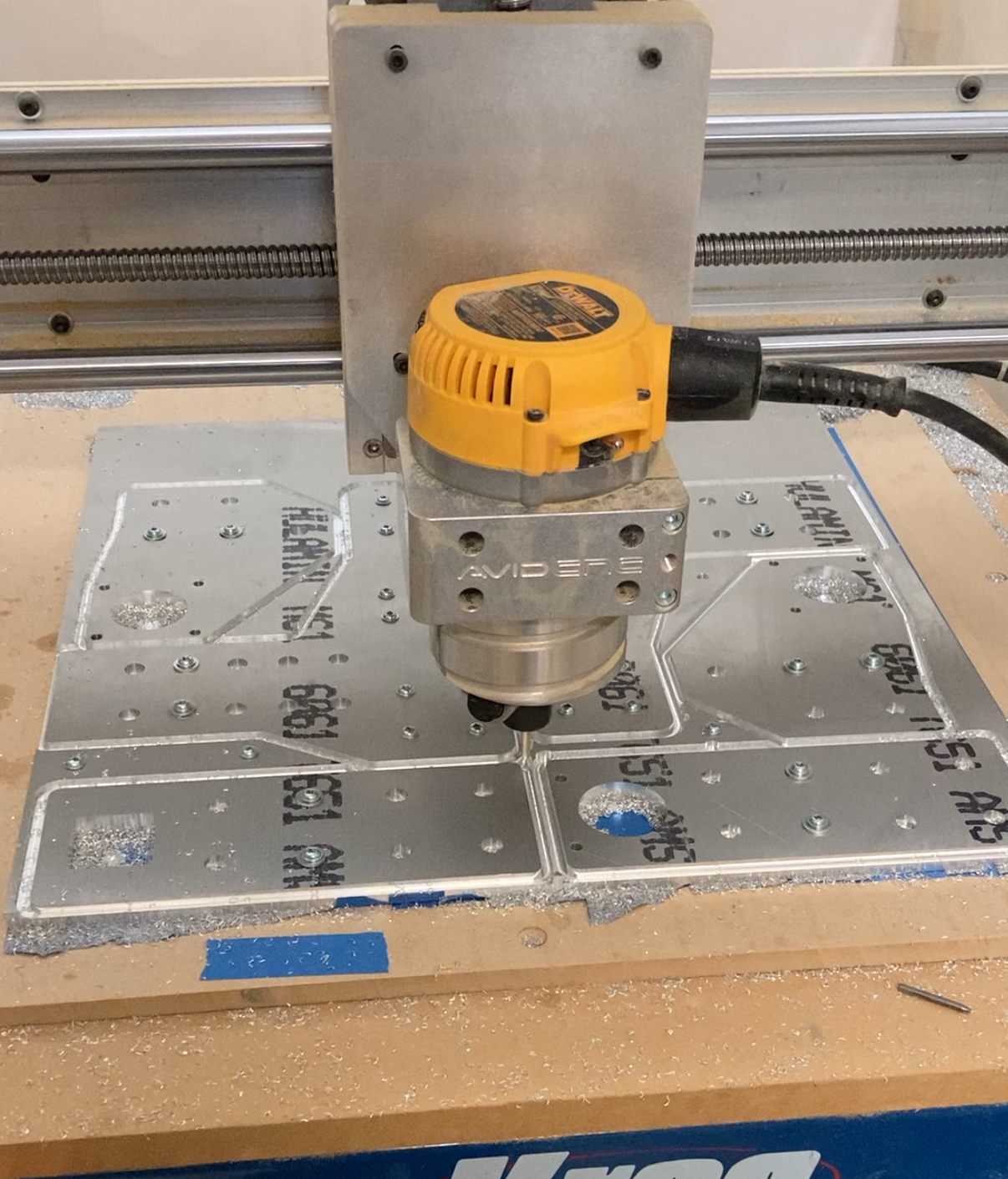

This project started with a simple goal: build a CNC machine entirely from the ground up and learn every step of the process. I used Fusion 360 to design the complete system—including the frame, motion components, and all mounting features for the motors, electronics, and structural assemblies. After finalizing the design, I fabricated every part myself using my older custom CNC setup.

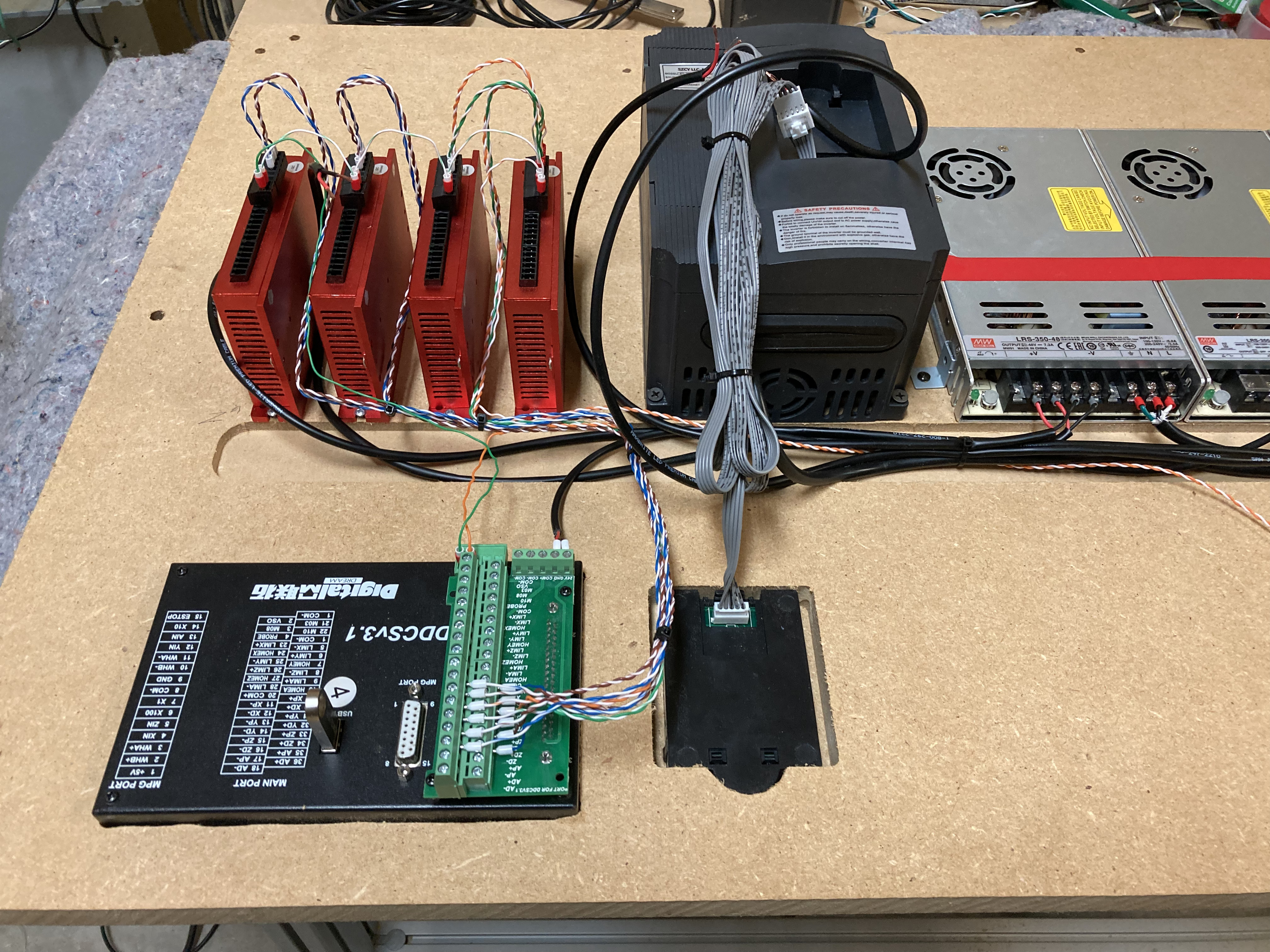

Once the mechanical build was complete, I wired the servo motors, drivers, power distribution, and control electronics. I also developed a custom post processor in Fusion 360, which required learning many core G-code functions and understanding how they interact with the controller. The final machine achieves excellent accuracy and repeatability, and it serves as a fully functional platform for machining custom parts.

Key Skills & Tools

Photos

A few views of the machine from design to final assembly.

Click any image to view a larger version.